Using this Dictionary Instructions

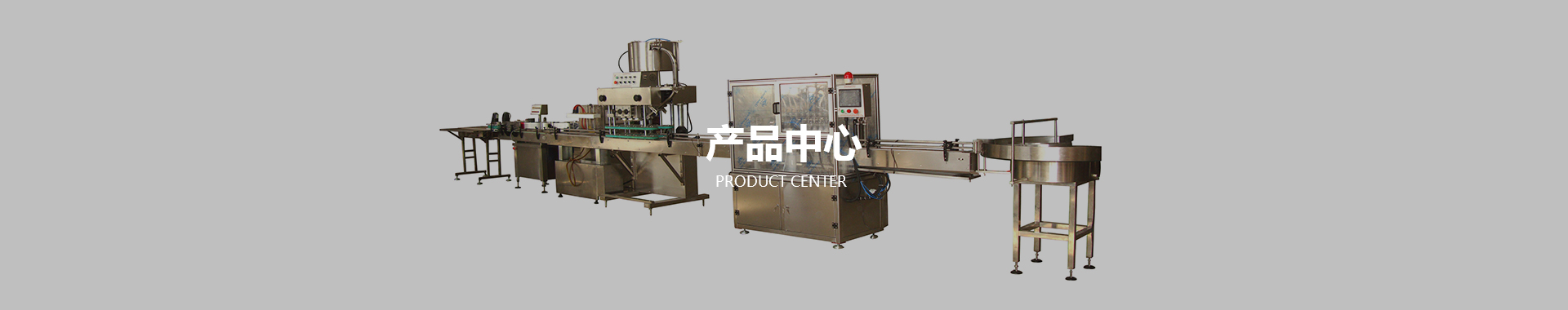

XGJ-6

type automatic inline screw capping machine by Shanghai Jiacheng company

recently improved capping machine.

The utility model has

the advantages of beautiful appearance, handiness, fast speed of capping and

high passing rate, and can be applied to different shaped bottle for screw capping

in food, pharmacy, daily chemicals, pesticides, cosmetics and other industries.

Four speed motor which are respectively used for cap feeding, clamping bottle ,

capping , transmission, and high degree of automation, good stability,

convenient adjustment and replacement of the bottle shaped or cap without spare

parts, only need to be adjusted to complete (if equip with feeding machine can

automatically the load cap to the vibration disk ).

Characteristic:

1. electromagnetic vibration sorting system, accurate screening

cap, more accurate and quick feed cap.

2.. The

operation space of the cap feeding track is large. It is controlled by the

regulating plate and the gate. It can be continuously supplied caps, complete

automatic production, save time and improve efficiency.

3.,

continuous split the bottle operation, free adjustment screw capping speed.

4.,

imported motor as the driving force of the screw cap, when reach torque will be

automatic brake, do not hurt the bottle cap, adjust the pressure level to determine

the bottle tightness.

5.,

torque size can be adjusted separately, you can freely adjust the tightness of

the screw cap.

6.,

change the packaging specifications, do not replace parts, only a simple

adjustment can be, easy to operate and easy maintenance.

Principle:

The bottle cap is

stored in the hopper, and is transmitted to the cap through a frequency

conversion lifting belt, and the capping function is realized by two

synchronous clamping belts and three groups of six screw cap wheels, and the

screw cap is made by mechanical torque adjusting function.

Technical parameters technical parameter

1, working voltage: 220V/50HZ - 60HZ

2, rated

power: 1500W

3,

production capacity: 60-100 bottles / min.

4,

bottle cap size: 15-70 mm

5, the

bottle diameter: 140 mm Phi Phi 25-

6, bottle

height: 38-300 mm

7,

exterior size: 1000*700*1600MM

8, net

weight: 250kg